CHALLENGES

Key Challenges in Manufacturing

-

Variability Kills Quality

Relying on memory or paper manuals leads to high variability and low first-time-fix rates, directly hurting quality assurance and overall throughput.

-

Costly Downtime

When a critical machine fails, technicians waste time searching documentation or waiting for remote experts, quickly escalating downtime costs and delaying production.

-

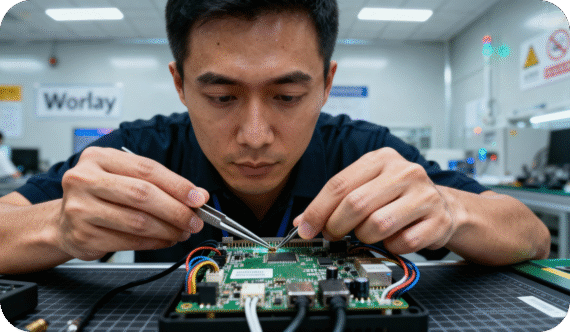

The Aging Skills Gap

New hires lack familiarity with complex digital machinery. The gap between tribal knowledge and formal training is widening, leading to slow employee ramp-up.

-

Inefficient Changeovers

Reconfiguring assembly lines for new product models requires time-consuming procedural checks, making the process prone to manual errors and reducing production time.

-

Audit and Compliance Risk

Conducting regulatory audits with paperwork is prone to manual checklist failures, creating severe compliance risk and increasing administrative overhead.

The Virtual Fudge Solution for AR-Driven Manufacturing Growth

Let’s be honest: in manufacturing, variance is the enemy of profit and throughput. That one seasoned technician who knows exactly where the tricky widget goes? When they retire, that knowledge walks right out the door with them. A waste of possibilites, if you ask us. Virtual Fudge can transforms this undocumented knowledge into repeatable, certified performance across all sites and shifts. Our AR solution provides precise guidance that’s cooler and much more efficient than any paper manual, solving the skills gap and accelerating operational efficacy from day one.

-

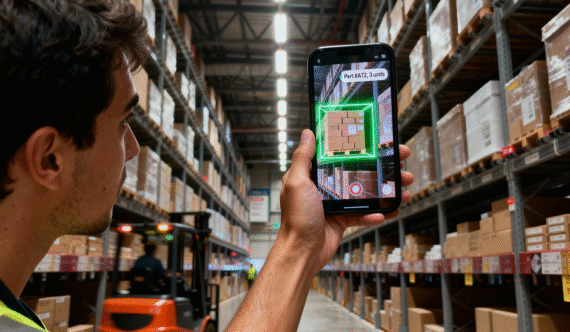

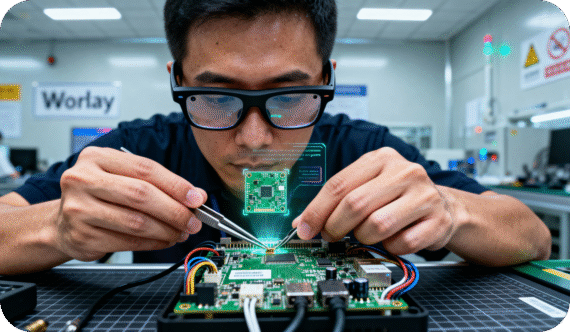

Digital Work Instructions (DWIs)

We retire those coffee-stained paper manuals. We replace them with crystal-clear, step-by-step 3D guidance overlaid directly onto the assembly line. This is your industrial GPS, ensuring every technician follows the precise, optimized path and crushing costly variability.

-

Remote Expert Guidance

Stop wasting days waiting for the senior expert to fly across the country! Our platform lets an offsite genius draw, annotate, and see exactly what the on-site technician sees in real-time. This instantly cuts downtime by accelerating troubleshooting and guaranteeing a first-time-fix rate globally.

-

Digital Quality Checks

Say goodbye to squinting at blueprints. Technicians simply use their device for an automated visual comparison against the perfect CAD model. This ensures product quality and compliance, catching defects before they become that massive, expensive pile of rework.

-

Skills Transfer Modules

We can capture the genius of your senior experts. By building repeatable AR flows from their actions, we preserve critical company knowledge, rapidly speeding up the time-to-competency for every new hire who joins the team.

-

Performance Analytics

We move beyond guesswork. Our system gives managers deep, unbiased data on every action, meticulously tracking task completion time, error rates, and compliance scores. This provides the precise evidence needed for process optimization and targeted, efficient re-training.

CHALLENGE

Traditional Marketing vs.

AR Marketing

TRADITIONAL MARKETING

- Binders & memory

- Slow ramp

- After‑the‑fact QA

MARKETING WITH VIRTUAL FUDGE AR

- Visual, verified execution

- Faster, safer starts

- In‑process prevention

Next-Gen Marketing

Launch Your AR Experience

in 3 Simple Steps

-

Step 1

Choose Your Win

We start by finding one workstation that has a clear, measurable problem, like frequent errors or too much downtime. We’ll work with your team to set specific goals for cutting scrap and boosting efficiency right there. -

Step 2

Capture the Genius

We record your best expert performing the task, then turn their method into a simple, step-by-step AR guide. This guide is immediately deployed to the line, training all shift leaders to use the new standard. -

Step 3

Prove and Expand

We track the results to show the exact improvement in quality and efficiency. Once the win is proven, we lock that improved process into your company standard and roll the solution out to similar production lines and sites.

Proven Results in

Manufacturing

-

60%

Increase on complex assembly processes

Source: ManufacturingTomorrow

-

25%

Reduction in rework and scrap

Source: PTC

-

40%

Training time acceleration

Source: PTC

-

50%

Shorter authoring time

Source: PTC

Augmented reality (AR) transforms manufacturing workflows

Inconsistency is the enemy of the factory floor. Yet, reliance on manuals and memory means every shift performs tasks differently. This leads to costly errors, slow training, and waste that isn’t caught until it’s too late.

AR changes everything. We replace outdated methods with clear, visual guidance. This speeds up onboarding, ensures safety, and catches mistakes in real-time—guaranteeing consistent quality from day one.

FAQ

WE DEPLOY THE SOLUTION AND PROVIDE YOU WITH DETAILED ANALYTICS TO TRACK ROI AND CUSTOMER ENGAGEMENT.

What is the proven ROI of implementing AR for digital work instructions?

How can AR help close the skills gap and reduce slow employee ramp-up time?

How does AR solve the problem of costly equipment downtime and remote support?